Should You Draw the Door Jamb in Plan

Contents

- Sizes and configuration

- Expendable materials and tools

- Stride-by-footstep education for installing interior doors

- Step one. Door-frame assembly

- Step two. Hinges installation

- Footstep 3. Door-frame installation and door slab hanging

- Pace 4. Foaming

- Step 5. Door lockset and handles installation into a door slab

- Step 6. Extension plates installation

- Step vii. The casings fastening

Practice-it-yourself installation of interior doors does not require specialized construction skills.

Some models are sold already assembled.

In other cases, door designs come up in disassembled form, which requires additional time and financial costs to install the door-frame and the door slab.

It is also necessary to decide beforehand whether the leaf opens to the slab or to the right, pull or push.

Below nosotros offering a step-by-step teaching on how to install an interior door correctly

Sizes and configuration

Back to the elevation

Prepare the following toolbox:

- A leveling tool to command the vertical position of the frame.

- Record measure, ruler, permanent marker, pencil for marking.

- A handsaw or a jigsaw for extensions and casings cutting.

- Electric drill, cordless perforator, spiral driver with forest and masonry drill chip sets.

- A milling cutter to be used as a hardware. If information technology'due south not there, a chisel with a hammer will do.

| Rough Opening Height, mm | Rough Opening Width, mm | The nominal size of the door slab, mm | |

| 2055-2060 | 700-710 | 2000 | 600 |

| 2055-2060 | 800-810 | 2000 | 700 |

| 2055-2060 | 900-910 | 2000 | 800 |

| 2055-2060 | 1000-1010 | 2000 | 600+600 |

| 2055-2060 | 1330-1340 | 2000 | 600+600 |

| 2055-2060 | 1530-1540 | 2000 | 700+700 |

Gear up wedges with different dimensions, which will be used equally a spacer for fixing the door-frame. Any instruction describing the interior doors installation says that self-borer screws are used to fix it. Determine at once how the fastening/fixing/attachment will be fabricated.

A subconscious assembly method is preferable, which will require lifting confined. A good alternative is to put /install the door-frame on the anchors. They demand to be screwed and pushed into the underground holes, which are and then spackled and repainted.

Expendable materials and tools

Back to the superlative

Expanding cream will be required. The installation of interior door slabs sometimes involves the need to narrow the rough opening. This involves the employ of brick, which ways that a finished cement-sand dry out masonry mixture is required. Store the container to dissolve it with water and to stir until you get a homogeneous mix.

Purchase a square trowel. It'due south skilful to have a scraper at mitt to remove the weatherboards before installing the casings made of MDF when the crude opening / hole in the wall is too large.

In other cases, both a wood chisel and a hammer will be required.

If after assembly of the frame and the door information technology will exist turned out that the rough opening is too small, you lot take to remove the elements of the wall panel and dispose of the waste, so prepare trash numberless.

If in that location are piece of furniture, household appliances and interior objects in the adjacent rooms, encompass them with polyethylene film.

The edges of the wall are treated with a spackle, mortar of cement. And to do that, you need an atomizer for humidifying, brushes for removing dust.

Step-by-step didactics for installing interior doors

Back to the top

In social club to install the doors on your own, it is enough to be able (know how) to apply the above-mentioned tools.

The procedure starts with measurements. They must be accurate, every bit a door frame with a slab is chosen on their footing.

- If you lot purchase a unit of measurement in disassembled form, you'll have to have the time to assemble the frame.

- All the intended hardware is built in: lockset, handles, barrel hinges.

- A door-frame is installed, verticality and compliance with the required dimensions are checked.

- The slab is attached with an installed hardware and the weatherboards are finished.

Before a door is installed, the superlative and width of the aperture must exist measured. This is done in three planes (along the flooring, ceiling and in the middle) and two vertices on each side. The pattern in this case shall not exist attached (tightly). The technological gap along the perimeter shall be betwixt 4'' and 15,vii'' (ten and forty centimeters).

Extensions are installed if the depth of the pigsty/rough opening is much greater than the door-frame.

The casings are installed subsequently the gaps are filled with expanding foam.

A more than detailed pace-by-step instruction includes 7 steps.

Footstep 1. Door-frame assembly

Back to the tiptop

It(the door-frame) is assembled from wooden bars stock-still/attached to each other in the form of a rectangle, unless a threshold is provided.

This type of interior door installation is used for WC, baths, technical rooms, balconies, greenhouses and storerooms, which must be closed tightly.

Other rooms has a P-shaped configuration in plan: I-configuration is used in other rooms: bedrooms, living rooms, dining rooms, etc. In that location are a number of features and nuances that you tin can deal with during the associates/process.

Splinting and Connecting Ways

Methods of the Door-frame assembly

At a 45-degree angle

A cute merely rather difficult way for an inexperienced builder. It is desirable to use a miter saw or a good hand mitre saw to saw the openings for buit-in equipment.

At a 90-caste bending

The near suitable choice for a practice-information technology*yourselfer without cabinet macker skills. Yous still have to use a mitre box to cut off the door-frame girder.

Recommended gap

The header is attached to the jambs with two self-tapping screws with anti-corrosion treatment.

Practiced advice

For self-borer screws that screw in into the MDF-elements, the holes must be pre-drilled with a drill bit, the diameter of which is iii quarters less than the size of the screws.

In virtually cases, the manufacturer himself saws the blanks for the door-frame according to the size of the slab. So it is enough to screw the design, fastening the elements with the screws included in the delivery package. If you have to exercise/first everything from scratch, the slab is taken, and the sidewalls, the upper beam and the threshold are cut forth information technology. Work is best washed on the floor.

In this instance, 2 methods of fastening are used:

ane. The header and stud are cut at an bending of 45 °. For people without cabinet maker skills, this method is hard. Boosted equipment will be required to do the even cut and right geometry Make holes for cocky-tapping screws. Their axes should be perpendicular to the cut. At the final stage, the parts are practical to each other, if desired, they are glued and attached with screws.

2. The plane of the cuts is perpendicular to the girder axis. The length of the side studs exceeds the height of the door slab past 0,12 in (3 mm) at the tiptop and bottom, if a threshold is provided. Otherwise, a gap of iii/8'''' (10 mm) is made at the lesser. To attach the header to the studs, 2 self-borer screws on each side are enough. The same applies to the sill beam.

Method 2 is the only ane for door-frames with a threshold. Therefore, earlier hanging doors with a wooden door (slab) and a frame, determine the type of crude opening, and on the basis of this, select the method of the door-frame installation. And practice not adjust the dimensions finish-to-stop. There should exist 0,12 in (3 mm) gaps on all sides, which are necessary to pull out the stud freely without jamming.

Connection of the door-frame elements

The sequence of the door-frame pattern

- On a level surface, on a floor or on 2 shifted tables, y'all accept to place a door-frame girder around the slab, and a cardboard is laid betwixt the slab and the door-frame to form a gap.

- The upper terminate faces of the vertical girders of the door-frame are provided with a blank of the horizontal upper plank and the verbal length of the header is measured;

- Saw cuts are ameliorate cut downwardly with pocket-size teeth hack saw

- Attach the peak of the door-frame(the header) to vertical girder; cardboard must be laid between the slab and the header to course the gap;

- When conjoining at right angles, the meeting stile preventing to attach the elements is commencement cut, then afterwards creating a level aeroplane; the screws are tighten up.

- If the saw cuts are made at an angle of 45°, the screws are turned perpendicular to the conjoining line through both girders;

- For door-frames without a threshold, the gap between the slab and the potential surface of the flooring cover shall be between v/sixteen'''' and 7/viii'''' (0.8 and 2.0 cm), depending on the purpose of the room and the type of flooring covering.

- The threshold is fabricated past analogy with the industry and attachment of the header at right angles.

Metallic screws having a length of non less than 23,vi in (lx mm) shall be used to tighten downwards the header with side studs. For the first, each side takes iii screws, while the other side takes two ones. To make the connexion tight, strong/durable and reliable, a quarter is removed. A hacksaw and a chisel with a hammer are used for that. The length of the hole is equal to the width of the girder used in the manufacture of the stud.

- Saw off the header of the size we want (using a triangle and a hacksaw)

- Mark places of openings for built-in equipment on the «plank» of the header (marked past red lines).

- Saw the openings on the plank of the header with a hacksaw (in society not to harm the «front surface» of the door-frame, it is possible to put on it, for case, a piece of thin tin can-plate, on the drawing it is painted with gray paint.

- With a sharp knife "cut through" (as securely every bit possible) along the line of the time to come horizontal cut, from both sides.

For those who want to know how to install an interior door without a threshold, you must remember that you can cut parts at an angle of 45 degrees, and you will not have to remove a quarter. Some other way is to install the header in width for the entire rough opening. This is necessary if it is significantly larger than the door-frame. And so the side supports are attached at correct angles to a width that satisfies the dimensions of the door slab.

Assembling a door-frame with a header equal to the width of the upper crude opening zone

Door-frames with a wide lintel/header are assembled for the crude openings arranging in brick or foam physical buildings to increment the bearing capacity and to ensure alignment with brickwork.

The length of header is equal to the width of the rough opening minus 1,96 in (5 mm). After sawing off a header of the desired length, draw the key centrality of the part, distances to the swivel and pretend girder are marked in both directions from it.

Further door-frame assembling actions are performed according to standard applied science.

Step 2. Hinges installation

Dorsum to the summit

This is one of mandatory point of the step-past-step interior door installation. The process requires special attention and accuracy. And so the slab will open up and close easily, without touching the door-frame, without friction or jamming. The stance that two butt hinges are enough is wrong. It is better to use iii turning knots (i.e., iii hinges). This will preclude the possibility of sagging. The outset point shall be placed in the identify where the meridian hinge is located, then the middle hinge, and after the lower one.

The apply of mortise and overhead hinge mechanisms is allowed. In the latter case, there is no need to make holes, otherwise, before installing the door, it is necessary to cut the material of the attachment size of the butt hinge on the slab and in the support. Marks of overall dimensions and places for fasteners are practical. After screwing in the self-tapping screws, the door-frame is installed vertically, the slab is hung and checked if it opens well and bears confronting the door-frame.

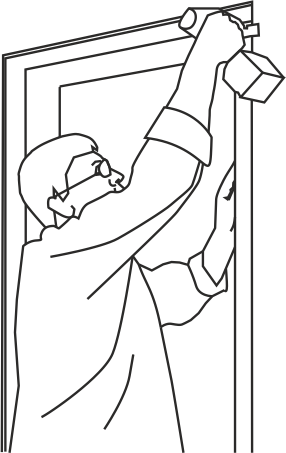

Step 3. Door-frame installation and door slab hanging

Back to the summit

Before installing, the crude opening should be prepared. The master thing is that at that place are no protrusions that preclude you from placing the door-frame. To install the door yourself, you need to remove the slab, and set the door-frame to a spirit level. Use a plumb rule to determine the deviation from the vertical axis.

MDF door installation options

For fixing MDF door-frames in the crude opening, information technology is recommended to use non self-tapping screws, only mounting metal plates used in the installation of drywall designs. Plates are often used in combination with anchor bolts. The number of fasteners is called depending on the forthcoming load.

The use of ballast plates is possible if a make clean finish has not yet been made. Their installation will require the shaving and levelling of walls afterward the door-frame is attached.

The pattern is opened in the rough opening by prepared wooden wedges. This shall be done first with one stud, and then with another, and then cheque the horizontality of the header and make control measurements.

The standard fixing method is anchoring. The jambs are drilled through and grooves are made in the face of the wall panel. This method of installation involves dowels from 5,nine'' (150 mm) in length, simply they will be visible. You lot will have to putty, glue or paint over.

The secret fastening is more complex. The fastener is a metallic profile, equally for plasterboard. The plates are attached to the wall with anchors. Offset, they make holes in the physical so that the fastening can be sparkled.

Then you need to insert/hang the door. To do this, it is placed on pre-prepared plates. Having raised the slab, it is necessary to ensure that the mechanisms of the barrel hinges are in their places. After that, bank check if it stands on the way of the door-frame when opening and endmost.

The operation of the hardware must also be checked. Past the way, handles and locksets are installed on the flooring before assembly. Now, information technology's of import that cypher interferes with the normal operation of the door. Open information technology half manner and make sure information technology keeps its own position, which is evidence of the verticality of the design.

Step 4. Foaming

Dorsum to the top

Rules for filling the gap with foam

The corners made of sawn timber scraps will assistance to precisely keep the centimeter technological gap under the polyurethane cream. Irresolute the depth of their immersion into the gap, at the aforementioned time marshal the door-frame in the opening.

It is better to buy foam with a dispenser. It is desirable to use it in portions. Beginning a sparse layer, then an boosted layer to fill all the space*gap*. In this way, the material can be saved, and not cut off excess/unnecessary cream after consolidation.

Now it's time to fill in the gaps betwixt the booth and the wall. Close the door. The foam is practical in layers, in sparse layers. Offset, the top of the volume is filled and then that the foam does not protrude outward under its own weight. If it gets on a visible surface, you must immediately wipe off the backlog with a dry textile.

When the foam has already hardened, use special means to remove the polyurethane foam. Subsequently finishing work it is better not to apply the doors for 24 hours. This is necessary for the consummate drying of the foam.

Step v. Door lockset and handles installation into a door slab

Back to the top

According to the installation rules, to perform this type of work, you need to remove the slab. If the manufacturer has not made holes and grooves, you volition have to make them yourselves. A milling cutter, chisels, drill are used. Locksets can be overhead and mortise. In the latter case, you will have to select the wood from the support, spiral on the encompass plate/overlays. And a lockset is inserted/screwed into the hole on the door slab with cocky-tapping screws. And then decorative cover plates/overlays are installed on the planes on both sides.

Merely present most of the locks are built into the handles. Manufacturers pre-make holes in which yous need to insert a handle with a bulldoze pin. On the other side the second part is fixed. Information technology is better not to change the installation order. The design is fastened with cocky-tapping screws come fitted with the handles. After screwing in, the faceplates are installed, which are fastened with latches. Subsequently that, the slab with hardware is placed on the awnings (hinges). It is of import to check that the deadbolt moves freely and does not jam.

Step vi. Extension plates installation

Back to the top

Pace by step educational activity at this stage of the installation looks like this

If the bar/plate is not function of the delivery package, buy the bar/plate of the aforementioned color.

Cut information technology in size so that the border of the wall is completely closed.

Set/install the lateral/bypass extension and then fasten/fix the upper one along the header.

Methods for fastening the door-frame expanded past the extension in the rough opening

- Door slab

- Door-frame girder/Jamb

- Extension

- Walls

- A plank, used to connect a door-frame to a extension

- Expanding foam

- Solid board or gypsum plasterboard plank

- A girder, glued forth the perimeter of the extension. Its size is calculated so that a 3/8 in gap (centimeter gap) remains between the girder and the wall.

- A girder, attached to the wall with screws forth the vertical jambs, screw it so that the distance between the wall and the mounting planks/rails can be adjusted

- Screws

Expert advice

The almost hard thing is to supplement the door-frame with extensions, installed in the rough opening. At that place are two ways to carry out the planned finishing:

- glue girders with a length of 11,811-15,748 in (thirty-twoscore cm) around the perimeter of the extension, so glue the extension to the door-frame and fill the infinite with expanding sealing foam;

- screw the timber to the wall with five or six self-tapping screws, adjust the position of this peculiar door frame, then insert the extension into the groove and fill the gap with foam.

In that location are several fixing options. Some modifications of the plates/planks are designed to be placed in special grooves. Another case is when the additional plank is pressed by the door-frame, which means that the installation is necessary during the detachment of the door-frame. L-casing systems are also found when the extension is fixed on both sides.

Pace 7. The casings fastening

Dorsum to the tiptop

Options for framing interior doors

A. Attach the vertical plates to the planned fastening betoken

B. Carefully mark the starting points of the future work piece cutting, saw it down according to the marks at an angle of 45 °

C. The cross casings, pre-cut at an angle of 45 degrees, is applied to the install location point and marker the second point.

Expert communication

Before terminal fastening, the operation of the door must exist checked: open up and close several times. The trims should non stand in the mode of the door slab movement.

A. Spike up the upper transverse/cross casing with the help of three galvanized or thin copper nails

B. Put a extensional/lineal vertical casing, installed from the side of the hinges location, mark the futurity cut line, exercise the same things with the opposite vertical casing

C. Adhere the casings to the door-frame

The face up of the door-frame should be flush with the wall surface. Attach the vertical piece to the header and make a cut mark that is ¼ in (one-half a centimeter) higher. Draw cutting lines, cutting off excess/unnecessary. At present utilize the side casings one afterward some other.

The main affair is that the line of contact on pinnacle is at an angle of 45°. To attach the casing to the jambs, nail them with nails without caps, then they will be invisible. Agglutinative binding is also used, but less efficiently. Better yet, utilize the combined method.

We too recommend to read:

Source: https://belwooddoors.com/en/articles/ustanovka-mezhkomnatnyh-dverej

0 Response to "Should You Draw the Door Jamb in Plan"

Post a Comment